Gearboxes and turbines work under constant stress. Heat, pressure, vibration, and friction all play a role in how these components age over time. Because they are often sealed systems, visual access is limited. This makes inspection tools essential for maintenance teams who need reliable insight without tearing equipment apart.

High-resolution videoscopes have changed how these inspections are handled. With sharper imaging and built-in measurement features, they allow inspectors to see problems early and make better decisions. From industrial plants to aviation and energy sectors, these tools help teams stay ahead of wear and unexpected failures.

Why gearbox and turbine inspections matter so much

Gearboxes and turbines are core parts of many machines. A small issue inside them can lead to serious damage if ignored. Pitting on a gear tooth, a crack on a turbine blade, or uneven wear on bearings may start small but grow fast.

Regular inspections help catch these problems before they lead to shutdowns. Visual inspection is one of the most effective ways to do this. When combined with high-resolution imaging, it becomes even more powerful.

What makes high-resolution imaging different

High-resolution videoscopes provide clearer and more detailed images than standard inspection tools. Instead of grainy visuals or blurred edges, inspectors get sharp views of surfaces and contours.

This clarity matters when looking for early signs of damage. Fine cracks, surface scoring, discoloration, and small chips are easier to spot. When inspectors can clearly see what is happening, they can assess severity with more confidence.

Seeing wear patterns more clearly

Wear rarely happens evenly. In gearboxes, certain teeth may show more stress than others. In turbines, specific blade areas may face higher heat or airflow. High-resolution imaging allows inspectors to study these wear patterns closely.

Clear visuals help teams understand how components are performing under real conditions. This insight supports better maintenance planning and helps prevent repeat issues after repairs.

Detecting defects at an earlier stage

Early defect detection is one of the biggest benefits of HD videoscopes. Small cracks or surface flaws often appear before major failure. With lower quality imaging, these signs may go unnoticed.

High-resolution views make it easier to identify defects while they are still manageable. This allows maintenance teams to schedule repairs during planned downtime instead of reacting to sudden breakdowns.

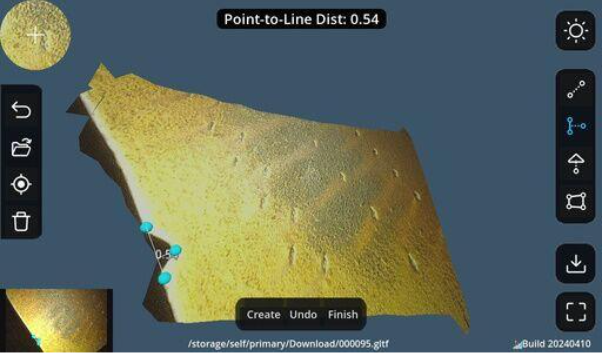

The value of accurate measurement tools

Many modern videoscopes include measurement features that work directly on captured images. These tools allow inspectors to estimate the size of cracks, pits, or worn areas without removing parts.

Accurate measurement helps in several ways. It supports maintenance decisions, improves reporting, and helps teams track changes over time. When inspectors can compare measurements from one inspection to the next, they can see whether a defect is growing or staying stable.

Supporting condition-based maintenance

Condition-based maintenance relies on real data instead of fixed schedules. High-resolution imaging and measurement tools provide the kind of data needed for this approach.

By monitoring wear and defects over time, teams can service gearboxes and turbines only when needed. This reduces unnecessary downtime and extends component life. It also helps avoid the risk of running equipment too long without inspection.

Improving access to hard-to-reach areas

Gearboxes and turbines often have complex internal layouts. Tight spaces, curved paths, and limited access points can make inspection difficult. Videoscopes are designed to navigate these spaces with minimal disruption.

High-resolution cameras ensure that even in these tight areas, image quality remains strong. Inspectors do not have to choose between access and clarity. They get both.

Better documentation and reporting

Clear images make better reports. When inspection findings are supported by sharp visuals, it becomes easier to explain issues to engineers, managers, or clients.

High-resolution videoscopes allow inspectors to capture photos and videos that clearly show defects. These visuals can be stored, shared, and reviewed later. Good documentation supports compliance, audits, and long-term maintenance planning.

Reducing unnecessary disassembly

Disassembling gearboxes or turbines takes time and carries risk. Each time a system is opened, there is potential for contamination or installation errors during reassembly.

With reliable visual inspection, many checks can be done without full disassembly. High-resolution imaging gives teams confidence in what they see, reducing the need to take machines apart just to confirm a suspicion.

Saving time during inspections

Time efficiency matters in maintenance operations. High-resolution videoscopes help inspectors work faster because they spend less time guessing or repositioning tools.

Clear images reduce the need to revisit the same area multiple times. Measurement tools reduce manual estimation. Together, these features streamline the inspection process while maintaining accuracy.

Supporting training and team consistency

Not every inspector has the same level of experience. High-resolution visuals help newer technicians learn faster by showing clear examples of wear and defects

Shared images from past inspections can be used for training. Teams can review what normal wear looks like versus damage that needs attention. This builds consistency across inspections and improves overall quality.

Enhancing decision-making with confidence

Maintenance decisions often involve balancing risk, cost, and timing. When inspection data is unclear, decisions become harder. High-resolution imaging removes much of that uncertainty.

When teams can clearly see defects and measure them accurately, they feel more confident. Whether the choice is to monitor, repair, or replace, it is based on solid visual evidence.

Adapting across industries and applications

High-resolution videoscopes are used across many industries, from aviation and power generation to manufacturing and marine operations. Gearboxes and turbines may differ in size and design, but inspection challenges remain similar.

A versatile videoscope with strong imaging and measurement capabilities can adapt to different environments. This makes it a valuable tool for teams working across varied equipment types.

Long-term value of advanced inspection tools

Investing in high-quality inspection tools pays off over time. Better inspections lead to fewer failures, longer component life, and more predictable maintenance schedules.

High-resolution videoscopes support proactive maintenance strategies. They help teams move away from reactive repairs and toward planned, informed actions.

A smarter way to evaluate critical components

Gearboxes and turbines will always require careful monitoring. As equipment becomes more advanced, inspection tools must keep pace. High-resolution videoscopes meet this need by offering clarity, precision, and practical measurement features.

They help maintenance teams see what matters, understand what they see, and act before small issues become major problems.

If you want to learn more about inspection solutions designed for detailed gearbox and turbine evaluations, reach out to USA Borescopes to learn more.

Contact them now.

Author Bio:

The author is a technical content writer who focuses on industrial inspection, maintenance tools, and reliability practices. They specialize in turning complex technical topics into clear and practical insights for professionals.