Understanding HDPE Sheets: A Sustainable Solution

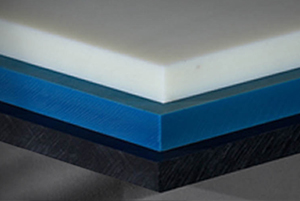

High-Density Polyethylene (HDPE) sheets have gained significant attention in various industries for their durability, versatility, and eco-friendly properties. As industries worldwide strive to reduce their environmental impact, HDPE sheets offer a practical and sustainable solution. Made from recyclable materials, these sheets are not only strong and resistant to chemicals but also contribute to reducing waste and promoting environmental conservation. Their widespread adoption in construction, agriculture, and other sectors underscores their value in modern industrial applications.

The Role of HDPE Sheets in Reducing Environmental Footprints

HDPE sheets are particularly valued for their role in minimizing environmental footprints. Unlike traditional materials that may contribute to pollution, HDPE sheets are recyclable and can be reused multiple times without losing their structural integrity. This recyclability reduces the demand for virgin materials, conserves natural resources, and decreases the amount of waste sent to landfills. Moreover, the production of HDPE sheets involves fewer greenhouse gas emissions compared to other plastic products, further contributing to environmental sustainability.

HDPE Sheets in Construction: A Green Alternative

In the construction industry, HDPE sheets have emerged as a green alternative to conventional building materials. Their durability and resistance to moisture, chemicals, and UV radiation make them ideal for a wide range of applications, including as a protective layer in roofing and wall systems. Additionally, HDPE sheets are used in geomembranes for lining landfills and containment ponds, ensuring that hazardous substances do not leach into the surrounding environment. By using HDPE sheets, construction companies can reduce their reliance on non-renewable resources and minimize their ecological impact.

Root Barrier Sheets: Protecting Ecosystems

Root barrier sheets, a specific application of HDPE sheets, play a crucial role in protecting ecosystems. These sheets are used in landscaping and agricultural settings to prevent invasive roots from damaging structures, such as foundations, sidewalks, and underground utilities. By containing root growth, Root Barrier Sheet help maintain the integrity of man-made structures while preserving the natural landscape. Moreover, they reduce the need for chemical root control methods, which can be harmful to the environment. The use of root barrier sheets is a testament to how HDPE sheets can contribute to sustainable practices in agriculture and landscaping.

Agricultural Applications of HDPE Sheets

HDPE sheets are also widely used in agriculture, where they serve multiple purposes, from greenhouse coverings to irrigation systems. Their resistance to UV radiation ensures that they can withstand harsh environmental conditions, making them a reliable choice for long-term agricultural projects. Additionally, HDPE sheets help in water conservation by lining canals and reservoirs, preventing water loss due to seepage. This application is particularly important in arid regions where water resources are scarce. By incorporating HDPE Sheet into agricultural practices, farmers can enhance their efficiency and reduce their environmental impact.

HDPE Sheets in Packaging: A Sustainable Choice

The packaging industry is another sector where HDPE sheets are making a difference. Their lightweight yet strong nature makes them ideal for producing reusable packaging materials, such as crates, containers, and pallets. Unlike single-use plastics that contribute to pollution, HDPE packaging can be recycled and reused, reducing waste and conserving resources. Furthermore, HDPE sheets are non-toxic and safe for packaging food and other sensitive products, aligning with the growing demand for sustainable and safe packaging solutions.

The Long-Term Environmental Impact of HDPE Sheets

The long-term environmental impact of HDPE sheets is overwhelmingly positive. Their durability means that they can be used for extended periods, reducing the need for frequent replacements and conserving resources. Additionally, at the end of their life cycle, HDPE sheets can be recycled and repurposed, further extending their usefulness and minimizing waste. As industries continue to prioritize sustainability, the adoption of HDPE sheets is likely to increase, driving innovation in eco-friendly industrial practices.

Conclusion

As industries across the globe seek sustainable solutions, HDPE sheets stand out for their environmental benefits and versatile applications. From construction to agriculture and packaging, these sheets provide a durable, recyclable, and eco-friendly alternative to traditional materials. By incorporating HDPE sheets into various industrial practices, businesses can significantly reduce their environmental impact while maintaining high standards of performance and reliability. Polycan Extrusion Pvt. Ltd continues to lead the way in producing high-quality HDPE sheets, contributing to a greener future for industries worldwide. To learn more about their products, visit plasticssheets.com.